I WANT

RELATED LINKS

I WANT

RELATED LINKS

RELATES LINKS

I WANT

RELATES LINKS

Services

Related Links

Use and Management of Cookies

We use cookies and other similar technologies on our website to enhance your browsing experience. For more information, please visit our Cookies Notice.

- Personal Banking

- Stories & Tips

- BUSINESS MAKER

- Change waste to success with Process & Lean Management

- Personal Banking

- ...

- Change waste to success with Process & Lean Management

Change waste to success with Process & Lean Management

21-10-2022

fat free body is agile and nimble Doing business is the same. fast-paced organization effective reduce wastage Of course, it is important to build a business to grow. Khun Kunlawach Phurichayawarodom (Por), Chief Executive Officer of Shonan Co., Ltd. shared business management tips for success to participants in the DIPROM AgriBiz Scale Up project seminar for SMEs. agriculture as follows.

Turn your business to success like ChouNan

Lean is a concept that tries to do everything possible to reduce waste in the production process continuously. Until there is no more useless thing Mr. Por said that the principle of Lean is to reduce time-expenses-processes to be as concise as possible. reduce the losses incurred In order to create maximum satisfaction for customers. However, loss reduction is an activity that has been done that does not create added value in the production process.

8 Wastes

Waste is any activity that does not generate value in production.

1. Transportation lost

2. Inventory lost

3. Motion loss

4. Waiting lost

5. Over production loss

6. Over process loss

7. Defect loss

8. Non-Utilized People ค

Six Sigma is therefore used to measure how much work is done and is a tool for detecting errors and helping to reduce costs.

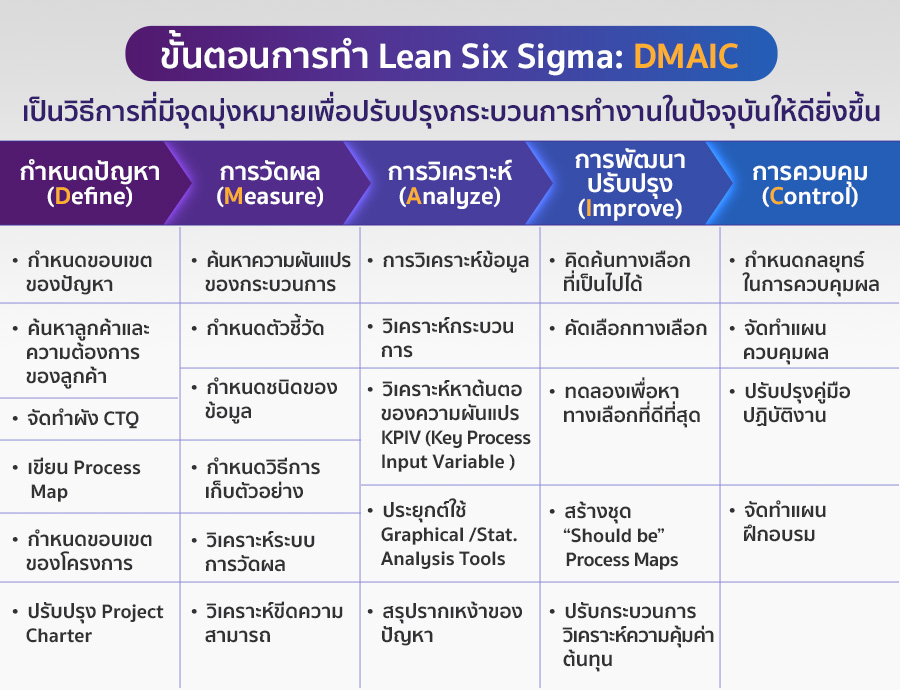

Thus, the combination of Lean + Six Sigma concepts yields powerful tools for problem solving and rapid process improvement. The Lean Six Sigma process consists of DMAIC.

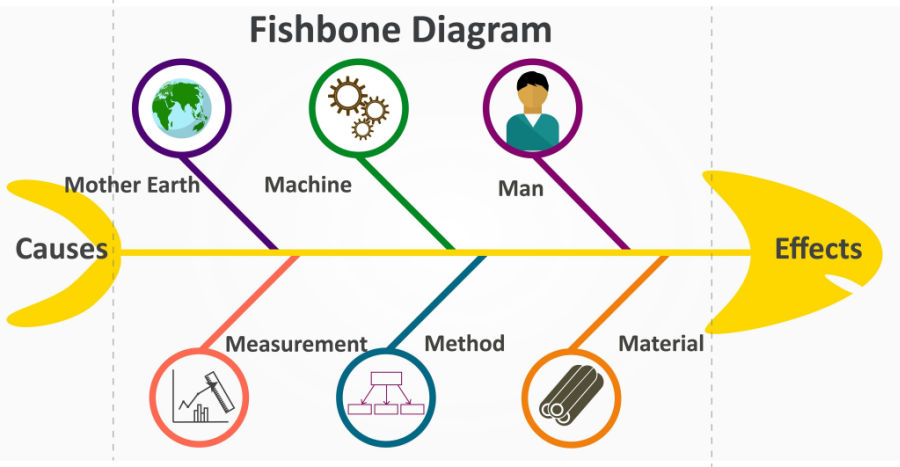

The most difficult step is D (Define) or defining the problem because you don't know what exactly is the problem. by separating the problem into separate matters Has done this by using the Fishbone Diagram to find the Cause & Effect and see what the problem is. and what urgent problems need to be solved

ChouNan way of doing business

Shonan emphasizes on 3 things: Fast-Comfort-Value, so every menu must be fast, delicious, easy to eat and worthwhile. So how does Shonan apply the Lean principle? Mr. Po gives an example. The most efficient arrangement of the store's kitchen in a limited space. Arranging the seating plan as much as possible or doing everything as standard to increase efficiency and reduce costs. Since the matter of raw materials.

In addition, Khun Por gave examples of innovation projects that employees have submitted to the contest. By adopting the Lean principle, warehouse workers have proposed a project, a new method of storing goods, sorted by frequency of use. This increases the efficiency of delivering goods faster than before, reducing time and reducing costs. As employees can apply the Lean principle, Mr. Po sees that success has been achieved. It's not about increasing profits or reducing costs. but to create a culture in the organization that makes everyone realize that If they help each other find new ways to improve work processes faster, reduce losses, then it will bring benefits both in terms of more efficient work and the employees themselves can work more conveniently and quickly.

Why food is not the heart of ChouNan

Although Shonan is a food business But Khun Por looked back. The most important thing is people because people can create people and hurt people. Therefore, Khun Por places importance on personnel development and training. Every week there must be training. There is an internal training course. And every year, there will be KPIs for all employees to train others. In order to practice skills in Coaching for employees to teach work as Because when they grow up, they will be able to continue teaching their subordinates. which now has adjusted the training process for new employees, leaving only 1 day, they can work immediately Because there is a manual that is updated until it is easy to understand, so the most important thing for business owners is to put everything in place and then adjust the work process to make everything lean as much as possible.

Fall, get up, learn, fight like ChouNan

During the past 3 years, restaurant businesses have all been affected by COVID-19, how did Khun Por stand up to fight? Po said If you compare Shonan to a graph, the line will be a vertical line that goes up steadily and then goes down. when this How to shape a business to create a new S Curve all the time. The trick is trial and error, try right, learn from mistakes. and always looking for new opportunities

The 2nd wave of COVID-19 creates a project "rice box", thinking of the campaign "how much we order, we help equally" when someone orders food for medical personnel, Shonan will contribute to the boxed meal as well. which is a campaign that can bring both business and merit. In addition, he also thought of doing ChouNan Shushi Corner to sell the store until he was able to create a new brand called "SOUL SHI". And Khun Por continues to build a brand. Including premium grill restaurants "SUMi TEi", Thai restaurants "Banjong", Vending Machine "Tu Kub Khao", which the Vending Machine project has been tried for about 7 months. Although sales are not as expected. but learned from failure and lead to new extensions Until becoming a boat noodle brand "Sao Na Yok"

It can be said that during COVID-19 Khun Po encountered the most battered test. But you can always get up and fight. Because Shonan has been Lean continuously until it causes maximum Efficiency. Most importantly, every employee in the organization has a culture of being a fighter, not giving up and ready to fight for the must Work From Home, must leave without Pay, but everyone is not afraid. It was fun to try new things and get a challenge. This is what Po said was the culture of the organization that he wanted it to be. because no matter what crisis If everyone fights together Obstacles can't make Shonan fall.

Khun Por still believes in Work Life Balance because he sees that Productive is not only about work. But also including balancing things in life, consisting of 4 aspects: body (rest, health, food), emotions (looking in reverse such as looking at the customer's point of view, looking far, looking broad, way of thinking (focus must be clear with your own standpoint and develop to what is focused), positive thinking will help us see some opportunities that we do not Used to think, sharing to be alms to benefit others. other organizations and society) and the soul must divide itself into parts. Both about work, myself and family.

Before parting, Khun Por said Everyone can overcome their own fears. If we can do that, we will find ourselves with unlimited potential. There are no limits to trying new things, and finally, to keep Shonan employees moving forward. Make the organization grow strong, that is the happiness and sustainable success of Shonan.

Source: DIPROM AgriBiz Scale Up Project Seminar for SMEs by Khun Kulwat Phurichayawarodom (Po), Chief Executive Officer, Shonan Co., Ltd. September 9, 2022, Siam Commercial Bank Headquarters