I WANT

RELATED LINKS

I WANT

RELATED LINKS

RELATES LINKS

I WANT

RELATES LINKS

Services

Related Links

Use and Management of Cookies

We use cookies and other similar technologies on our website to enhance your browsing experience. For more information, please visit our Cookies Notice.

- Personal Banking

- Stories & Tips

- Success Story

- LEAN is the Answer for New Normal Business

- Personal Banking

- ...

- LEAN is the Answer for New Normal Business

LEAN is the Answer for New Normal Business

18-01-2021

In the rapidly-changing business world, the business that quickly adapts to change will have a competitive advantage. The concept of Lean will drive organizations to optimal performance without waste, like those who are healthy without body fat. Khun Paveepat Wattanasiriseth, Managing Director of Qualiwood Co., Ltd., the manufacturer of wood pallet, wood container and wood packaging for the export industry, together with Dr. Suriya Lertwattanapongchai, Course Director of NIA-SCB Innovation Based Enterprise II (IBE), have shared the principles and experience in implementing Lean Management which can be applicable for SME entrepreneurs.

The heart of LEAN in the business

The key principle or the heart of Lean is to creating more value for customers and reducing manufacturing waste which is an unseen money leak. Entrepreneurs can reduce costs by implementing Lean seriously because profit comes from cost reduction, not a price increase. When the price goes down, you’ll have an advantage when comparing with the competitors. Khun Paveepat said that the principles of Lean do not limit to manufacturing business but Lean can be adapted to service business or trading. Dr. Suriya added that Lean can be applied to almost all business processes such as Customer Journey, Production, Production Support, Logistics, Procurement, Supply Chain, HR Services, Financial and Accounting, IT, and Sales & Marketing.

The 5 principles and the 7 wastes of Lean

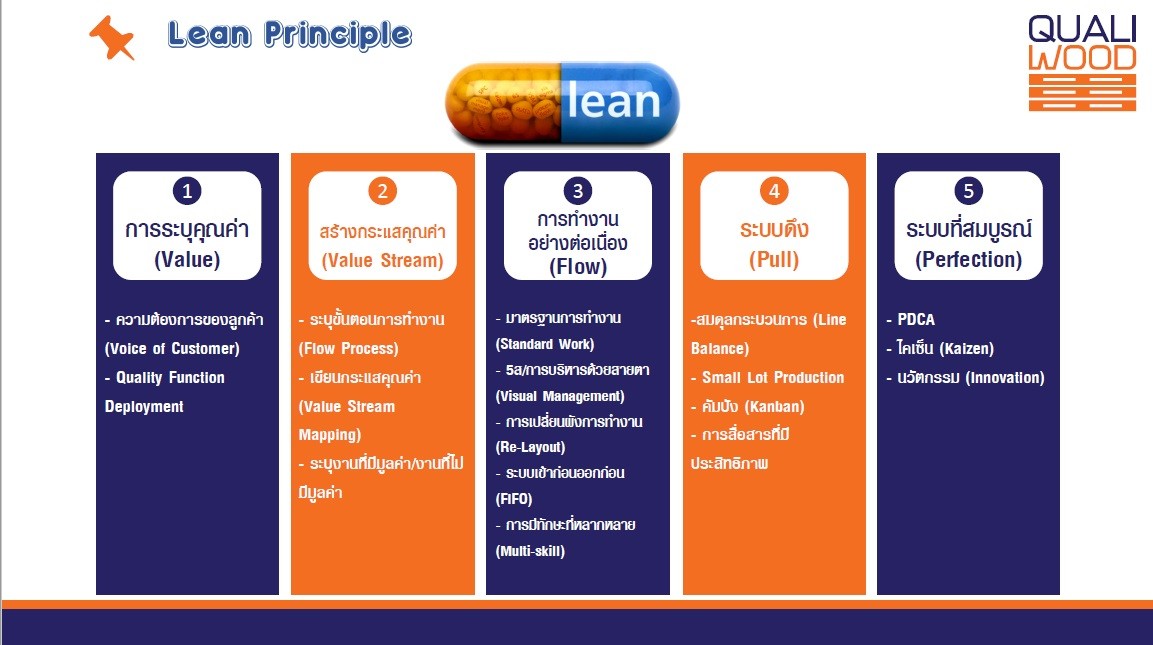

The 5 principles of Lean are as follows:

1) Define the value: Considering whether you’ve offered value to customers and that value is worthwhile for them, and they really want it. If it is unwanted value, your product will be unreasonably expensive. Thus, you have to deliver proper value based on customers. Customer voices are key to help entrepreneurs know their problems or pain points and to provide value that responding to customer needs. In the perspective of Khun Paveepat, the business doesn’t compete for profits but value that offers to customers and society.

2) Create value trend: Monitoring which area of workflow, products, and customers are wasteful by using Value Stream Mapping (VSM). The VSM technique is to write a flowchart documenting every step in the work process to check which process is excessive, to analyze which process is time-consuming or over-labored, which job is value or unvalued, and to track which area is a bottleneck. Overall, VSM is a health check for manufacturing and services in the business.

3) Flow: Managing the workflow to run quickly and eliminate bottlenecks against obstruction according to the 7 wastes of Lean, and use technology management to improve workflow to run smoothly towards the end of the process. For example, Implementing Standard Working procedures, The 5 Principles of Lean, First In First Out (FIFO), etc.

4) Pull and Balance: Using high technology to create balance of demand and supply (Capacity) by management principles such as Line Balance, Small Lot Production, Kanban, including effective communication.

5) Perfection: Conducting ongoing measures of development by PDCA (Plan Do Check Act). If the outcome is good, set it as a standard. If not, verify and find defects and then make better and continual improvement. The key is not to be easily satisfied because satisfaction is an enemy of increasing manufacturing efficiency and obstructing development.

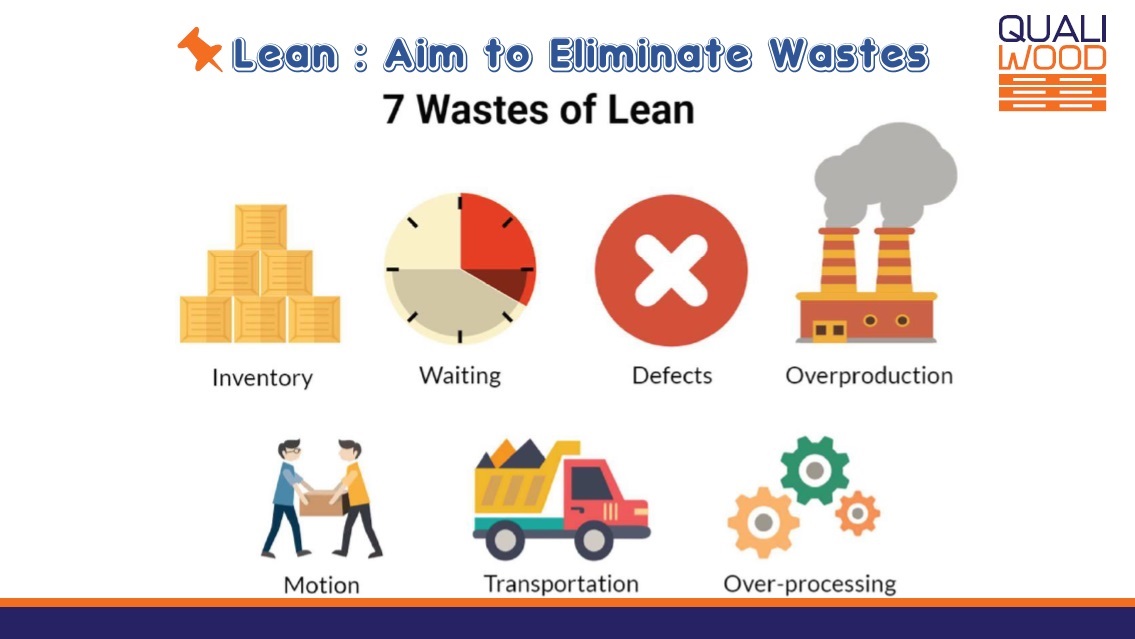

The 5 principles of Lean are addressed to eliminate the 7 wastes that undermine the working performance as follows.

1. Time: Waiting is a waste of time such as waiting for production and transportation, etc.

2. Motion: Good pattern and the flow of work help reduce unnecessary physical movement and enhance working efficiency, for example, placing things at the proper height so staff don’t need stretching, or arranging floor plan in the restaurant so waiters/waitresses are agile in providing service for customers.

3. Transportation: Arrange an effective transportation route.

4. Defect: If there’s a defect in the job, it wastes time, raw materials, and workforce to fix everything.

5. Inventory: The products are overstock.

6. Over-production: The products are over manufactured.

7. Over-processing: The product exceeds customer demands. That means you added more value to a product than the customers actually require or the product has too much or complicated process that leads to wastes.

Dr. Suriya also added another waste called Talent waste which may happen when talented employees haven’t been assigned to work in accordance with their capability.

LEAN index

Khun Paveepat emphasized that we must eliminate duplicate or redundant processes which considered as part of the 7 wastes to reduce cost and increase work efficiency, reflecting through measure indexes such as Lead time, Manufacturing Cycle Time, and Dock to Dock Time. Short lead time means low waste while long lead time means high waste. Measurement also includes percentages of Inventory Turn, On time Delivery, Overall Equipment Effectiveness, Right First Time, People Productivity and Floor Space Utilization, etc.

Where to start LEAN

The difficulty in implementing Lean management is to change working behavior in the past because most employees get used to it and feel that all changes are their burden. Khun Paveepat focuses on changing and developing a better work process at all times. Lean management can be successful if it’s started by the business owner as an initiator and leader to change the organization seriously. “We have to think like Start-Up (build the business to Exponential growth), run the business as SME (the Executive approaches customers), and own the Public company status (standard work process and high price is unnecessary)”, said Khun Paveepat.

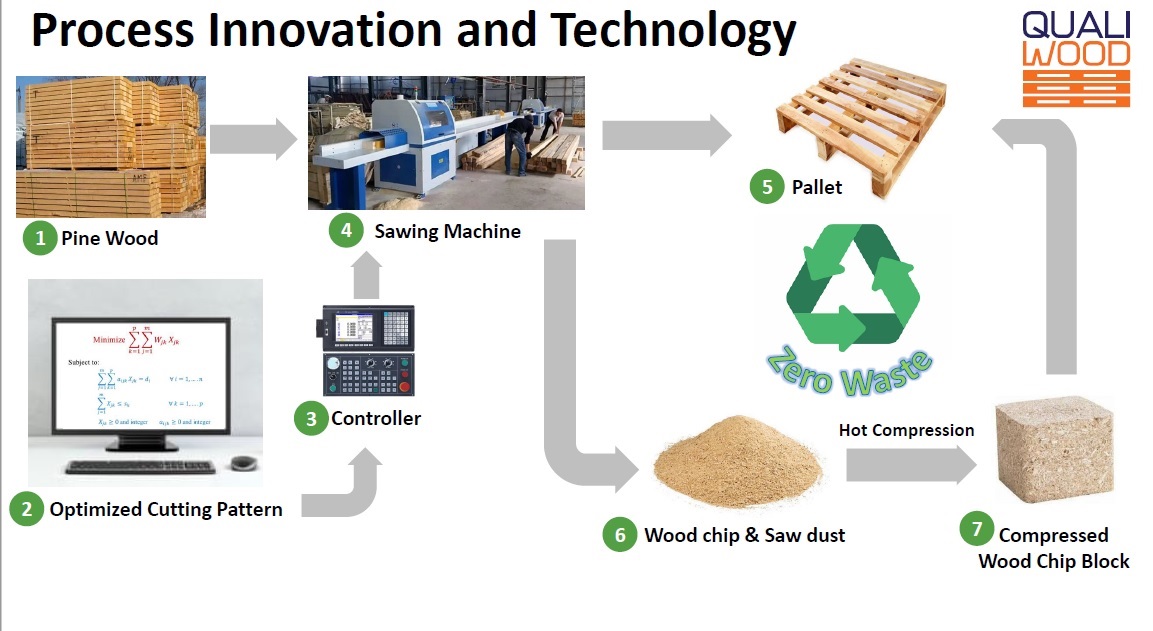

He also mentioned about Zero Waste Wooden Pallet that uses the Optimization method. That is to create wood cutting techniques to build pallets by leaving the least of wood chips in order to minimize waste from unwanted wood. Also, to take the number of wood chips to press, go through the recycling process, and then turn to wooden pallet components. “Entrepreneurs should consider what is waste and which type of materials can be reused or recycled to reduce waste, and that’s all about money”. All techniques above mentioned reinforce the standpoint of Qualiwood as an organization that is friendly to this world, and Qualiwood business is directly related to the environment. “Lean in our manufacturing process is in line with the concept GO LEAN, GET GREEN, which helps minimize carbon dioxide emission in several activities from cutting wood, manufacturing, transportation, and wood chips disposal, to protect the environment and our world. We commit to Creating Share Value (CSV). Our business delivers value to society so we have gained a good reputation. When customers use our products, they are part of a green supply chain and help preserve the world environment. That is an advantage that attracts customers”.

For business management, Khun Paveepat suggested not to be a monopoly sticking with only one supplier but we should diversify in order to have variety of customer groups. “At Qualiwood, the customer volume is never larger than 50% and customers include several categories. The business is diversified and also sells some other products. We don’t manufacture paper carton but we take it from other brand and sell it, and we have made good sales”.

Adaptation is required for a business that needs to survive in the changing and competitive world. The organizations that undergo LEAN will be agile and full of efficiency to quickly adapt themselves. They’ll continue growing and developing, have higher potential, and are ready to face new challenges in the future. The NIA-SCB Innovation-Based Enterprise ll (IBE) Course took 10 weeks and was arranged from November 2020 – February 2021. The interested person may follow course details at www.scb.co.th และ https://scbsme.scb.co.th/

Source: NIA-SCB Innovation-Based Enterprise II (IBE) Training Course, conducted by Khun Paveepat Wattanasiriseth, MD, Qualiwood Co., Ltd. and Dr. Suriya Lertwattanapongchai, January 13, 2021